Noncontact Eddy Current Sheet Resistance Meter for Thick and Curved Materials

Up to five significant digits available, depending on instrument range.

| Instrument Range | Dynamic Range in Ohms/square | Significant Digits Available at Each Order of Magnitude | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Low End | High End | 10k | 1k | 100 | 10 | 1 | .1 | .01 | .001 | |

| ×10 | 5 | 100,000 | 1 | 2 | 3 | 4 | 5 | |||

| ×1 | .5 | 10,000 | 1 | 2 | 3 | 4 | 5 | |||

| ÷10 | .05 | 1,000 | 1 | 2 | 3 | 4 | 5 | |||

| ÷100 | .005 | 100 | 1 | 2 | 3 | 4 | 5 | |||

| Reading rate: | 30 ms |

| Reading display rate: | 240 ms (instrument displays the average of eight readings) |

| Reading drift with temperature: | No more than .125% of total resolution per degree Celsius per hour |

| Gap size: | Gap between sensor and material can vary, but it must be carefully controlled |

| Minimum sample size: | 3 cm diameter circle |

| Spatial resolution: | 3 cm diameter circle |

| Maximum sample thickness: | Accommodates infinite nonconductive substrates |

| Reach in web: | Not applicable |

All options and upgrades are available for purchase with the original unit and for at least one year after purchase.

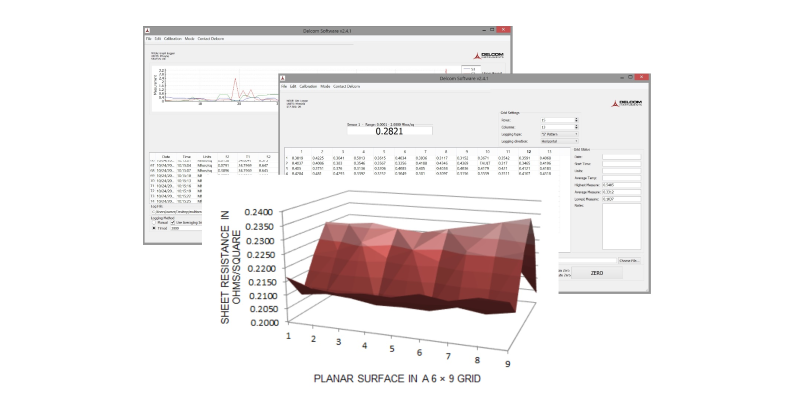

PC-based software upgrade:

This configuration does not require software for operation; however, Delcom’s productivity software is a very valuable tool. Delcom's powerful software has many useful features, allowing users to set pass/fail thresholds, monitor multiple sensors at once, save data for further analysis, and more. It is designed to make common tasks as fluid, intuitive, and easy as possible. The software requires a PC running Windows XP or newer OS.

Additional sensors:

The 873 Interface Module can accommodate up to 12 sensors. A user may want to purchase additional sensors in order to increase the range of the entire system or to take measurements at two or more physical locations.

S3 stage:

The sensor is designed to be used without a stage. However, a stage is recommended for applications requiring a high level of precision. The stage will hold the elevation of the conductive layer flush with the sensor and allow for better xy positioning of the material above the sensor.

Optional computer:

Delcom can source a laptop, desktop, tablet, or industrial touchpanel PC for customers, if needed.